System Problems & Solutions for Piping Systems

Problem with your system? We have the solution.

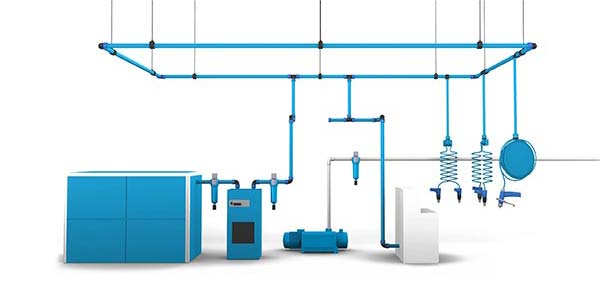

Compressed air piping systems can experience a variety of challenges and CAG Technologies specializes in reliable solutions to help you better distribute your compressed air throughout your facility effectively and efficiently. In order to assist you in solving your compressed air piping system challenges we have listed some of the most common problems users of compressed air piping systems can experience on a regular basis. Take a tour of our list of the typical compressed air piping system problems that plant Managers experience regularly and see recommended solutions that we have provided. Feel free to contact us for solutions.

- If the pipe system is steel and rusting downstream it may need to be cleaned and or replaced

- A system with particles and rust must be serviced more frequently

- Check to ensure that proper filtration is installed

- Ensure air treatment is not in by-pass mode and dryer is working properly

- Ensure water separator is working properly

- Check if all of the filter housings in the line have had the filter elements replaced recently

- Replace filter elements with new OEM filter elements or a high-quality after-market product

- For critical air lines remove poor quality filter housings and replace with a higher quality filter product

- Drains will need to be checked and serviced or replaced frequently

- Replace old pipe system with new technology anti rust aluminum piping systems

- See our solutions: Compressed Air Filters Products, Alternative Filter Elements Products, Drain Products, Pipe Systems Products

- Piping is contaminated and not serviced properly

- Piping system is too small and may require a correctly sized pipe system in order to reduce pressure drop

- Air Compressor air/oil separator and air filters require service

- Filters in the system are likely not sized properly for system capacity

- Replace downstream filter elements in the system

- Aluminum pipe systems provide less pressure drop due to smooth internal pipe finish verses black steel pipe systems

- See our solutions: FAI Products, Alternative Filter Element Products, Pipe System Products

- Adding piping can be difficult as it requires qualified personnel to install new and add-on systems

- Finding mechanical contractors and materials to add in new piping can take weeks or even months

- Our Purestream Aluminum piping system is lightweight, easy to install and fully approved for all provinces across Canada

- Purstream piping can be adapted to connect to most other types of existing piping systems

- Purestream piping is readily available from stock across Canada

- See our solutions: Pipe System Products

- Small leaks can create huge energy losses and added costs due to over use of air compressor as well as excessive wear and tear on the compressor system

- Reduced air flow due to leaks

- It is essential to find and repair pipe system leaks that in many cases are undetected

- Call in your service provider to do an air audit to determine where the leaks are in your system and then have them repaired

- Replace piping system with Purestream leak free aluminum pipe systems which will make it more efficient and add to your bottom line

- See our solutions: Leak Detectors, Pipe System Products

- Black pipe systems in your plant must be identified/marked as a compressed air line, nitrogen line or vacuum line, requiring the piping system to be manually marked accordingly which requires time and effort by staff

- Purestream piping is available in blue (compressed air), green (nitrogen) and grey (vacuum) making it easily identifiable and cosmetically appealing as well as making it easier for your staff to identify when required

- See our solutions: Pipe System Products

Welcome to CAG Technologies

What can we help you with today?

Please choose from one of our product categories below and one of our technical specialists will assist you promptly.